What's Inside?

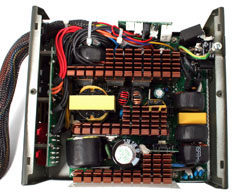

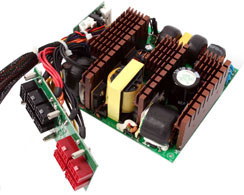

Six Philips head screws later and we're looking at the In-Win from the inside-out. The fan should be familiar by now as we've seen the large Yate Loons before on several other PSUs. It's generally a very quiet runner, despite being dual ball bearing, and while well balanced it's notably uneven to stop when flicked (unlike premium fans like the Sanyo Denki from Seasonic for example).Classified as a high flow 12V, 2,800RPM fan with 140CFM of airflow and belting out 48.5dB noise at full speed, it's thankfully well regulated to far lower speeds when operational.

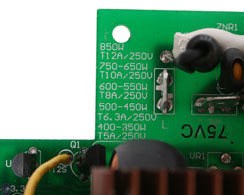

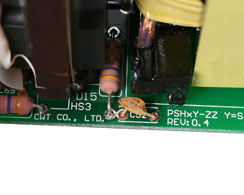

The build is almost identical to a generic CWT model, and the PCB further gives this away by listing models from 350W up to In-Win's 850W Commander, and even this 750W is missing some black ground cables soldered to it.

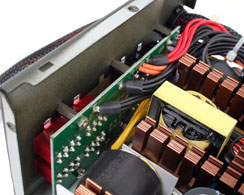

To keep the cost down, but also limiting efficiency, In-Win doesn't use a DC-DC converter, instead relying on the more traditional approach of having two AC-DC converters - one for 12V and another for 3.3 and 5V. The four rails are regulated from a single 12V transformer via overcurrent protection from one of the daughterboards standing up inside.

Generally the build quality is very good with every component securely fitted, although some of the hand soldering underneath is a little messy. The anodised aluminium fins are rippled for extra surface area and are orientated to direct the air out towards the exhaust at the back of the case. Not a single solid aluminium capacitor is used, but the single large capacitor is an 85'C Hitachi, while most/all of the rest (we couldn't see a few) are Samxon 105'C. The "GF" series are used to reduce the ripple, and it's the only method In-Win employs.

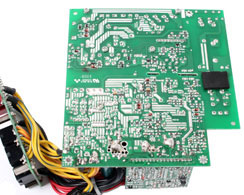

The modular board is very secure and well made, but getting it off required ripping off the entire sticker over them. Determining which rail is which is also easy too thanks to the colour coded +12V cables.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.